Built-in ice txiag (cov khoom seem rau LE308G)

Ice Maker Specification

1 Sab nrauv Dimension 294 * 500 * 1026mm

2 Rated voltage AC 220V / 120W

3 Compressor Voltage 300W

4 Dej Tank Peev Xwm 1.5L

5 Ice Storage Capacity 3.5Kg

6 Lub Sijhawm Ua Dej Khov Thov

1) Ib puag ncig kub 10 degree -90min

2) Ib puag ncig kub 25 degree -150min

3) Ib puag ncig kub 42 degree -200min

7 Net Nyhav Txog 30Kg

8 Ice dispensing ntim Txog 90-120g / 2S

Maintenance Principles

★ Cov cuab yeej siv niaj hnub: txav tau tus ciaj ntswj, steel hlau pliers, taw tes taw, lub taub hau tiaj tus thiab tus ntoo khaub lig ntsia hlau, ntsuas cwj mem, daim kab xev tus pas me me txhuam, hairdryer thiab lwm yam.Thermal melt gun, Wiring pliers.

★ Cov cuab yeej: ntsuas ntsuas siab, ntau lub ntsuas, clamp ammeters, hluav taws xob ntsuas hluav taws xob cov ntsuas kub, thiab lwm yam.

★ Kev tu lub tshuab tub yees: lub tshuab nqus tsev twj tso kua mis tub yees, Ni-trog encylinders, siab nyemvalves, filling pipes, quantitative fillers, acetylene cylinders, oxygen cylinders, Vuam phom, yeeb nkab bender, yeeb nkab ex pander, yeeb nkab cutter peb-txoj kev valve, sealing clamp, thiab lwm yam.

Maintenance Principles

★ Sab nraud ua ntej Internal: Ua ntej tshem tawm cov kev cuam tshuam ntawm sab nraud, thiab tom qab ntawd xyuas qhov tsis ua haujlwm ntawm lub tshuab ua dej khov.

★ Hluav taws xob ua ntej txias: Ua ntej tshem tawm cov hluav taws xob ua txhaum, xyuas kom lub compressor khiav ib txwm, thiab tom qab ntawd xav txog qhov ua txhaum ntawm lub tub yees.

★ Cov xwm txheej ua ntej cov khoom siv: Yog tias lub tshuab compressor tsis ua haujlwm, yuav tsum xub xyuas seb qhov kev ua haujlwm voltage xav tau rau kev ua haujlwm puas muaj, seb puas muaj teeb meem nrog lub tshuab hluav taws xob thiab ntsuas kub thiab thaum kawg xav txog lub com-pressernws tus kheej.

★ Yooj yim ua ntej nyuaj: ua ntej txheeb xyuas qhov yooj yim-rau-tsim, feem ntau thiab ib qho txhaum, thiab ua ntej xyuas qhov tsis yooj yim thiab yooj yim-rau-disassemble qhov chaw, tom qab ntawd xav txog kev sib xyaw ua ke, qis qis qis thiab cov khoom siv disassembled nyuaj.

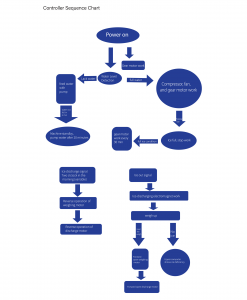

3 ua iceUa Tshuab Kho Cov Txheej Txheem thiab Kev Tshuaj Xyuas Cov Txheej Txheem ntawm Cov Khoom Loj

★Txhim kho cov txheej txheem ntawm lub tub yees: saib xyuas cov tub yees sab hauv thiab sab nraud cov raj xa cua txias cua → lub siab thiab cov pa tawm kom pom → hloov cov cuab yeej lossis kho cov tshuab xau los ntawm kev hloov cov lim qhuav> Nqus extraction txhaj tshuaj refrigerant → sealing

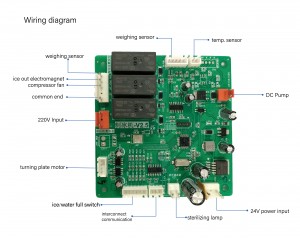

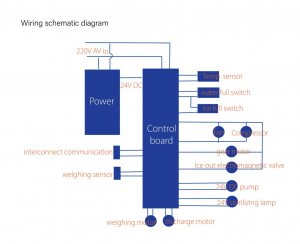

★ Cov txheej txheem tswj xyuas hluav taws xob: seb cov khoom siv hluav taws xob puas yog

Ua kom tiav seb txoj kev sib txuas puas yog raws li daim duab kos duab> seb puas muaj qhov luv luv lossis Circuit Court tawg tshwm sim qhov xwm txheej rwb thaiv tsev → Tshawb xyuas seb lub tshuab hluav taws xob compressor thiab overload tiv thaiv puas zoo → kuaj xyuas qhov pib ua haujlwm

★ Compressor:

A / Kuaj qhov tsis kam ntawm txhua qhov cua ntawm Compressor: Tshem tawm cov hlua hluav taws xob → Tshem tawm cov relay ntawm lub compressor Ntsuas qhov tsis kam ntawm txhua qhov Cuab Yeej (Tus nqi tsis kam ntawm qhov kev khiav hauj lwm kawg mus rau qhov kawg + kev tiv thaiv tus nqi los ntawm qhov pib kawg mus rau feem ntau kawg = tus nqi tiv thaiv los ntawm qhov kawg khiav mus rau qhov pib kawg).

B / Kho lub ohmmeter mus rau qhov siab tshaj plaws iav thiab ntsuas qhov tsis kam ntawm lub davhlau ya nyob twg rau hauv av.lf ib pawg ntawm windingpom tias yog luv luv rau hauv av los yog tus nqi kuj yog me me, ces lub compressor tawm ntawm kev txiav txim.

Kev daws teeb meem

| Ua tsis tiav | Fault phenomena | Tshawb xyuas qhov ua rau ua haujlwm tsis zoo | Kev daws teeb meem | |

| 1 | Tsis muaj dej khov | 1.Tsis muaj dej khov thaum lub tshuab ua dej khov ua haujlwm | Xyuas seb lub compressor thiab kiv cua puas ua haujlwm zoo, thiab siv ntau lub 'meter' los ntsuas qhov tso zis voltage ntawm pawg tswj hwm | Yog tias lub rooj tsavxwm PCB tsis muaj qhov tso tawm, tus maub los yuav tsum tau hloov lossis compressor kiv cua puas yuav tsum tau hloov |

| 2.Tsis muaj dej khov thaum Compressors thiab ice-making motors ua haujlwm | Xyuas seb puas muaj dej (dej theem hauv lub tank dej);seb qhov nqus thiab tso pa kub yog qhov qub | Cov dej qis qhia tias dej tsis txaus float hloov mus rau ntau tshaj 4 feeb kuj tseem qhia txog dej tsis txaus;Yog tias tso pa tawm thiab nqus qhov kub siab, nws yuav tsum yog cov dej xau (tsis muaj dej, ntxiv kua) | ||

| 3.Compressor kiv cua ua haujlwm, dej khov ua lub cav tsis ua haujlwm | Xyuas seb lub PCB pawg thawj coj saib puas muaj qhov tso zis hluav taws xob thiab seb lub cav puas puas lawm;Xyuas seb cov ntsia hlau puas khov | Yog tias lub rooj tsavxwm PCB tsis muaj qhov tso tawm, tus maub los yuav tsum tau hloov.Yog hais tias lub cev muaj zog hloov lub cev muaj zog Yog tias cov ntsia hlau khov, nws yuav tsum qhib lub tshuab los xyuas seb lub hau ntswj thiab lub tshuab txiav puas puas thiab yuav tsum tau hloov; yog tias cov ntsia hlau tsis puas thiab khov lub tshuab tuaj yeem ua haujlwm. los ntawm hluav taws xob. | ||

| 2 | Dej khov tsis tuaj | 1. Tsis muaj dej khov tawm thaum lub tshuab tau txais cov lus qhia rau kev tso dej khov. | Xyuas seb lub tshuab hluav taws xob puas tau qhib thiab seb lub tshuab ua dej khov puas tig | Hloov electromagnet los yog PCB board; Ice ua lub cev muaj zog txoj kev yog tib yam li uas tsis muaj dej khov |

| Seb lub cev hnyav ua haujlwm (kaw, qhib) | Seb lub cev lub cev hnyav puas lossis PCB puas lawm.Yog puas, thov hloov | ||

| Ice paug lub cev muaj zog tsis ua haujlwm lossis ua haujlwm rov qab | Puas yog lub tshuab hluav taws xob tso tawm puas lossis PCB puas lawm?Yog puas, thov hloov. | ||

| 3 | Cov dej khov yog fragmen-ted thiab muaj dej ntau. | 1. Cov dej khov tuaj tawg thiab poob rau hauv cov roj teeb. | 1. Dej khov yog crushed thaum nws ua2.Dej khov yog crushed thaum nws yog stirred. | 1. Cov riam yuav tsum tau hloov; 2.lim phaj yuav tsum tau hloov thiab lub qhov hluav taws xob qhov hluav taws xob npog phaj yuav tsum tau kho |

| 2. Cov dej khov muaj cov ntsiab lus dej loj thiab tsis yooj yim rau swb | 1. Dej khov yog crushed thaum nws ua2.Dej khov yog crushed thaum nws yog stirred. | Ditto.Qee qhov tunnels tuaj yeem muab ntxiv rau cov riam khov nab kuab los ua kom cov dej khov ua haujlwm. | ||

| 4 | Cov dej khov uas tawm los tsis ruaj khov. | 1. Dej khov ntau: Xyuas seb cov dej khov puas yog cov khoom qab zib uas muaj dej ntau | Dej khov los hauv cov roj teeb. | Tshem tawm tag nrho cov dej khov hauv lub thoob dej khov thiab kho cov dej khov zoo xws li txoj kev No 3 saum toj no |

| 2. Tsawg dej khov | 1. Tsis muaj dej khov txaus hauv lub thoob dej khov2.Puas muaj tej yam txawv teb chaws nyob rau hauv cov dej khov skating khiav uas tiv thaiv cov dej khov ntawm zawv zawg? | Nws yog ib qho tsim nyog los kho qhov system kom pom qhov tsis muaj dej khov nyob rau hauv lub computer sab saud kom tshem tawm cov swb thiab ua kom cov dej khov poob zoo. |